About Department

Mechanical Engineering Department was established in the year 2011 with intake of 60 students. The department is also offering a three years diploma programme with the intake of 60.

The courses develop the knowledge and skills in the areas of Automobile engineering, Power plant engineering, Industrial engineering, Production engineering, Design engineering, Management subjects etc. as per the syllabus prescribed by JNTUA, Anantapuramu, A.P.

The department is a unique blend of young minds and experienced hands. It has got the faculty with specialization in Thermal Engineering, Energy Systems, Refrigeration and Air conditioning, Production Engineering, CAD/CAM, Machine Design, Industrial Engineering etc. Some of the faculty has rich industrial experience.

The department has sophisticated and well established laboratories. The labs include Heat Transfer, Instrumentation and Control System, Metrology, Machine Tools, Thermal Engineering, Computer Aided Design, Manufacturing Technology lab, Material science and Computer Aided Manufacturing lab.

Mechanical Department organizes regular seminars, workshops and guest lectures by eminent personalities having academic as well as industry profile. The department has developed good rapport with many industries in and around Nellore district and organize industry visits for students every semester. Placement focused training in various software like Auto CAD, Catia, Creo and ANSYS is imparted to the students through Organizations specialized in the field and has MoUs with them.

All deserving candidates were placed in companies like CadSys, Thermal Power Tech, Nelcast Ltd, Sankar JP sealings, Infac India Ltd, Greentech Industries, Balaji Industries, Think & Learn, Infosys, YSI Automotive Pvt.Ltd.,etc. through campus recruitment drive.

Few had passion for higher studies and joined Masters in USA, Canada, Germany and in India. A handful of students became entrepreneurs. The department encourages students having innovative ideas and provide guidance for the execution of projects through EISC cell of SVCN.

In the department of Mechanical Engineering, “we don’t limit our challenges……we challenge our limits”.

VISION

To originate a prominent Centre for empowering the students with professional skills for Innovative research & Entrepreneurship in Mechanical Engineering enriched with morals and societal Responsibilities.

MISSION:

M1: Preparing Dynamic Mechanical Engineering graduates suitable for emerging Industrial requirements under Passionate Academicians through Outstanding Education.

M2: Employ modern methods, pedagogy and state of art facilities for continuous improvement in Innovative Research and Entrepreneurship skills.

M3: Instill the essence of Morals and Societal responsibility in students.

PROGRAMME EDUCATION OBJECTIVES (PEOS)

PEO 1: Graduates will have fundamental knowledge in engineering to undertake Challenges in design, development and analysis related to mechanical Engineering as required by presentacademia and industry.

PEO 2: Graduates adapt the changes in technology and pursue Mechanical Engineering related research to develop innovative and sustainable Solutions to societal needs.

PEO 3: Graduates will be able to establish initiatives of entrepreneurship, innovation and start-ups to demonstrate professional leadership and skills to work in multidisciplinary teams,with good communicative abilities and ethical values.

PROGRAM OUTCOMES

PO1: Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

PO2: Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

PO3: Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

PO4: Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

PO5: Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

PO6: The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

PO7: Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

PO8: Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

PO9: Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

PO10: Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

PO11: Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

PO12:Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

PROGRAM SPECIFIC OUTCOMES (PSOs)

PSO 1: Engineering Design: Achieve effective and optimized design solutions in product design with the knowledge obtained in material science, manufacturing and thermal engineering.

PSO2: Engineering Analysis: Analyze, interpret and provide solutions to real life mechanical engineering problems of industry and society.

Syllabus

S.No | Regulation | View |

1 | R20 | |

2 | R19 | |

3 | R15 |

cOURSE OUTCOMES

S.No | Regulation | View |

1 | R15 Regulation |

List of Faculty

| S. No. | Name | Designation |

|---|---|---|

| 1. | Dr. P. Jaya Prakash | HOD and Controller of Examination Cell |

| 2. | Dr. D Ramakrishna | Associate Professor& Incharge R&D Cell |

| 3. | M. R. S. Subrahmanyam | Assistant Professor |

| 4. | S. S. Ravi Sankar | Assistant Professor |

| 5. | V. Varun Kumar | Assistant Professor |

| 6. | Y. Siva Krishna | Assistant Professor |

| 7. | J. Hareesh Kumar | Assistant Professor |

| 8. | N. Jashuva | Assistant Professor |

| 9. | E. Bhaskar | Assistant Professor |

| 10. | D. V. Saiteja | Assistant Professor |

| 11. | B. Jagadeesh | Assistant Professor |

DEPARTMENT OF MECHANICAL ENGINEERING

LABORATORIES

CAM LAB

Computer aided manufacturing is designed to prepare students as entry – level machinists in many areas including manufacturing, fabrication, aerospace sectors & also as CNC operator and CNC programmer.Students will study machining processes and procedures using CNC lathe & mill.

Students will program and operate the machining centres & turning centres in the lab which actually provides hands on experience , so that they get enough knowledge prior getting placements.

THERMAL ENGINEERING LAB

Thermal Engineering lab has equipment like four stroke Diesel and Petrol engines, Reciprocating compressor and engine cut models. Performance on engines has been carried to find the performance parameters like thermal efficiency, specific fuel consumption etc. Also with the help of cut models of engines the VTD and PTD can be studied.

MECHANICS OF SOLIDS LAB

Mechanics of Solids lab has variety of equipment like Universal Testing Machine, Brinell’s Hardness testing machine, Impact testing machines. The strength of any engineering material is very important. It has to be tested for various parameters like strength, stiffness, hardness, toughness etc. which will be carried in Mechanics of Solids lab.

FLUID MECHANICS & MACHINERY LAB

Fluid Mechanics and Hydraulic Machines lab has all the equipment to study basic properties of fluids like Bernoulli’s equipment and to study about various hydraulic machines like Pelton wheel, Francis turbine, Kaplan turbine and Pumps like Centrifugal pump and Reciprocating Pump.

MACHINE TOOLS LAB

After production exercise in the curriculum through engineering workshop and Manufacturing Technology labs MACHINE TOOLS LAB is added. This lab adds the customer requirements such as Drilling to fit the job into the casing . Reaming, Boring, Thread cutting, knurling, sharpening the tool, surface finishing are the operations done .Cutting keyway slot , Gear cutting operations were done as per requirement

ENGINEERING WORKSHOP

Basic Engineering Workshop has equipment to study important trades like Fitting, Carpentry, Tin Smithy, House wiring. It is common and included in syllabus for all branches of engineering studies.

HEAT TRANSFER LAB

Heat Transfer lab is having variety of equipment to study basic modes of heat transfer phenomena like conduction, convection and radiation. Also equipment available to study phase change heat transfer like boiling and condensation.

Faculty Participations

FDP’S ,WORKSHOPS,WEBINARS OF ACADEMIC YEAR 2022-23 Click Here

FDP’S ,WORKSHOPS,WEBINARS OF ACADEMIC YEAR 2021-22 Click Here

FDP’S ,WORKSHOPS,WEBINARS OF ACADEMIC YEAR 2020-21 Click Here

FDP’S ,WORKSHOPS,WEBINARS OF ACADEMIC YEAR 2019-20 Click Here

Publications

S.No | Academic Year: 2022-23 | View |

1 | Fabrication of solar operated multipurpose floor cleaning machine by Shafee S.M.& P. Kumar Babu | |

2 | Design and fabrication of power generation system by using gym equipment by Shafee S.M.& SS Ravisankar | |

3 | Fabrication of cut –off engine by detecting alcohol content of the person by M. Mercy Lydia & P.Kumar Babu | |

4 | Fabrication of wireless haptic robotic arm by Shafee S.M.&; Sk Zakir Hussain | |

5 | Design and fabrication of foot step power generation by P. Kumar Babu.&; Mrs.Subrahmanyam | |

6 | Fabrication of multipurpose agricultural machine by B. Haritha Bai &; P. Kumar Babu | |

7 | Design and fabrication of regenerative braking system by Shafee S.M &; P. Kumar Babu | |

8 | A zinc based aluminium alloy analysis and an improved alloy fabrication using za25 and za37 by Shafee S.M &; P. Kumar Babu &; A.Bhargav &; G.Vijay Kumar in IJFANS | |

9 | Analysis on mechanical characteristics of concrete made with natural fibre reinforced polymer and significant development using hybrid composites by S.S. Ravi Shankar & V.Abhinay &; M.Mercy Lydia &; S.M. Shafee in IJFANS | |

10 | Swift water freezers design and construction study using thermoelectric modules by Shafee S.M &; M. Mercy Lydia &; . V.Varun Kumar &; S.S.Ravisankar in INDUSTRIAL ENGINEERING JOURNAL | |

11 | An analysis of friction stir welding of marine grade 5083 aluminium alloy using weld parameters by G.Vijay kumar & S.S. Ravi Shankar &; Mrs.Subrahmanyam & P. Kumar babu in INDUSTRIAL ENGINEERING | |

12 | Influence of ferric oxide and titanium dioxide nano particles to minimize energy demand in buildings by integration of solar collectors and phase change materials by S.M. Shafee in MATERIALS TODAY | |

13 | A fatigue study on ribs and spars used for designing and finite element analysis of an aircraft wing at different winglet angles by V.Varun Kumar &; B.Haritha Bai & Y.Siva Krishna &; SK.Zakir Hussain in JOURNAL OF THE ASIATIC SOCIETY OF MUMBAI VOL:XCV.NO.1(VIII)Pg. No: 958-965 ISSN:0972-0766 2022 | |

14 | An essential technique for wavy fin concert evaluation of a four stroke petrol engine during heat transfer by Mrs.Subrahmanyam & B.Haritha Bai & V.Varun Kumar & SK.Zakir Hussain in JOURNAL OF THE ASIATIC SOCIETY OF MUMBAI VOL:XCV.NO.1(VIII) Pg. No: 946-950ISSN:0972-0766 2022 |

S.No | Academic Year: 2021-22 | View |

1 | Structural And Thermal Analysis Of Gas Turbine Rotor Blade , P.Kumar Babu, V. Abhinay, | |

2 | Design And Fabrication Of Hybrid Energy Generation System, A.Bhargav & M Mercy Lydia | |

3 | Design And Fabrication Of Pedal Operated Forklift, V.Varun Kumar & M Mercy Lydia, | |

4 | Delineation And Analysis Of Non-Inflated Tires, P.Kumar Babu & M Mercy Lydia,. | |

5 | Topology Optimization And Structural Analysis Of Wing Attaching Bracket Of Aircraft, P.Kumar Babu & B Haritha Bhai, | |

6 | Design & Fabrication Of Multipurpose Mechanical Machine, P.Kumar Babu & M Mercy Lydia, | |

7 | Thermal Analysis Of Fins With Different Geometries And Materials For Electronic Cooling, P.Kumar Babu & Sk.Zakir Hussain, | |

8 | Design & Fabrication Of Multipurpose Agricultural Vehicle, MRS.Subrahmanyam & M Mercy Lydia, | |

9 | Fabrication Of Compressed Air Vehicle, Siddeswar Rao & M Mercy Lydia, | |

10 | Modelling And Analysis Of Engine Cylinder Fin Body By Using Different Geometry & Materials, P.Kumar Babu & S.S.Ravi Shankar, | |

11 | Design And Simulation Injector 3304 D By Laser Power Bed Fusion Method, P.Kumar Babu & Mr. S.M.Shafee, | |

12 | A Study Of Wearable Robotic Devices Designed For Flexibility And Power Assisting Voice Commands Using Catia V5 , S.M.Shafee, M. Mercy Lydia, V. Abhinay, P. Kumar Babu, | |

13 | Conical Exhaust On Different Users Cfd And Thermal Study Using Ansys Analysis Modules, S.S. Ravishankar, V.Varun Kumar, Sk. Zakir Hussain, A.Bhargav, | |

14 | Cfd And Micro-Fin Performance Analysis On Three Similar Heat Exchanger Tube Bundles For Reduction Of Pressure, JOURNAL OF FUNDAMENTAL AND COMPARATIVE RESEARCH, VOL:8, NO.1(X), Pg. No: 418-427, MRS Subrahmanyam, Ch.V. Rajesh, B. Harithabai, S.S.Ravisankar, ISSN: 2277-7067 in 2021. | |

15 | A Flexible Machining Technology For Highly Accuracy Powder Mixing Processing Using Edm Technology, JOURNAL OF FUNDAMENTAL AND COMPARATIVE RESEARCH, VOL:8, NO.1(X), Pg. No: 434-439, A. Bhargav, P. Manoj Kumar, Y. Siva Krishna, V. Varun Kumar, ISSN: 2277-7067 in 2021. |

S.No | Academic Year: 2020-21 | View |

1 | Fabrication Of Spring Coil Suspension System And Generation Of Electric Power , A.Bhargav, | |

2 | Studies On Tribological Behaviour Of Zno Nanorods Suspended In Sae 20w40 Engine Oil, SOLID STATE COMMUNICATIONS, S.M.Shafee, . | |

3 | Computational Anlaysis Of Heat Exchanger And Maximized Heat Transfer Rate By Using The Double Tube Helical Coil,P.Kumar Babu, | |

4 | Heat Transfer Analysis Of In-Wheel Electric Motor Housing With Different Cooling Fin Arrangement Using Ansys, P.Kumar Babu, . | |

5 | Study And Thermal Analysis On Turbulent Nanofluid Flow In Helical Tube Heat Exhangers,P.Kumar Babu . | |

6 | Analysis Of Heat Transfer Mechanisms In The Solidification Of Pcm With Different Passive Enhancement Techniques For Free Cooling Applications, IT IN INDUSTRY, S.M.Shafee | |

7 | Regression Analysis On Resource Constrained Project Scheduling Based On Critic Method ,A.Bhargav, | |

8 | Performance Analysis Of A Vertical Axis Wind Turbine With Different Shapes Of Blades, S.M.Shafee, | |

9 | Design And Analysis Of Cantilever Beam By Using Creo And Ansys Software, P.Kumar Babu,. | |

10 | Analysed Design Of Air Craft Wing Structure Using Pro-Engineering Wildfire 5.0, P.Kumar Babu, | |

11 | Experimental Analysis On Anaerobic Digestion Of Industrial Waste Biomass, AIP CONFERENCE PROCEEDINGS, S.M.Shafee, | |

12 | Malfunctioned Mode Effect Analysis To Identify And Eliminate The Current And Future Problems In A Company, IIIE, VOL:49, ISSUE:07, Pg. No: 35-39, S.M.Shafee, Ch.V.Rajesh, Sk.M. Isahaak, V. Gopala Krishna, ISSN: 0970-2555 in JULY,2020. |

Patents

S.No | Academic Year | View |

1 | 2022-23 | |

2 | 2021-22 |

STUDENT PARTICIPATION

S.No | Academic Year | View |

1 | 2022-23 | |

2 | 2021-22 | |

3 | 2020-21 | |

4 | 2019-20 |

STUDENT PUBLICATION

S.No | Academic Year | View |

1 | 2022-23 | |

2 | 2021-22 |

INTERNSHIPS

S.No | Year | View |

1 | 2021-22 | |

2 | 2020-21 |

INDUSTRY VISIT

S.No | Year | View |

1 | 2022-23 | |

2 | 2021-22 |

PLACEMENTS

S.no | Academic Year | View |

1 | Placements record for AY:2021-22 | |

2 | Placements record for AY:2020-21 | |

3 | Placements record for AY:2019-20 |

STUDENTS RESOURCES FOR SELF LEARNING

The Institute strongly believes in providing various self-learning facilities to the student community through which the subject can be induced in a better manner. The following are the various facilities offered by the institute for self-learning.

1. Internet facility

2. Digital Library

3. Virtual Labs

4. Department library.

5. E-learning Resources for Students

6. Tutorial Classes

1. High speed Internet facility: Internet facility has been provided through net links leased line and also through a private provider by installing receiver in the campus.

Sree Venkateswara College of Engineering is having 200 Mbps Internet connections, locally networked and connected through Wi-Fi. All the Laboratories of different department are having Internet facility connected through intelligent switches. The entire college campus covered with 15 Wi-Fi Access points to access Internet and Intranet educational resources. With this addition the college will provide internet and intranet access to all students for instructional purpose on par with colleges internationally.

1.1 Available Internet connection

Reliance Jio Digital (50mbps).

NET LINKS online services (100mbps).

1.2. Wi-Fi facilities

The department corridors are connected with wireless

15 Wi-Fi Routers connected across the campus for Students.

2. Digital Library has been established in the central library with 30 computers

Established in the central library equipped by 30 computers with internet connection.

CD ROMs around 500 are available.

Availability of e-Journals 450 & e-books from DEL NET

Previous years question papers of JNTUA

E-books for all the courses available in DEL NET

Project reports

Support to students for self-learning through NPTEL videos

Virtual Labs

S.No | NAME OF THE LAB | VIRTUAL LINKS |

1 | STRENGTH OF MATERIALS LAB | |

2 | 3D PRINTING VIRTUAL SIMULATION LAB | |

3 | DOM LAB | |

4 | MECHANICS OF MACHINES LAB | |

5 | ENERGY STORAGE LAB | |

6 | SOLAR ENERGY LABS | |

7 | MECHANISMS AND ROBOTICS LAB | |

8 | CIM LAB | |

9 | HEAT TRANSFER & THERMODYNAMICS LAB |

Youtube Videos

S.No | HEAT TRANSFER | View |

1 |

S.No | FLUID MECHANICS | View |

1 | ||

2 |

S.No | THERMAL ENGINEERING -I | View |

1 | ||

2 |

MESA (MECHANICAL ENGINEERING STUDENTS ASSOCIATION)

MESA is a professional association formed from and for the benefit of the

students of Department of Mechanical Engineering at Sree Venkateswara College of

Engineering, Nellore.

The main aim of the association is to encourage the students to show their ability

to perform in technical and non-technical activities and as a whole to develop a student

of Mechanical Engineering into a complete technocrat.

In pursuit of this various activities have been conducted like Paper Presentations,

Project Expo, Quiz programmes, Work Shops, Poster Exhibits and Guest Lectures for

exploring the inherent talents of the students and paving the way to reach their goals.

Students Association Activities | ||||

Department of Mechanical Engineering | ||||

| S. No | Programme | Name of the Speaker or organization | Topic | Month & Year |

| 1 | Guest Lecture | Mr. Fareed Basha, Branch Manager, CANTER CADD, Nellore. | Career Guidance for Mechanical Engineers – CAD & Modelling Tools | 24.1.22 |

| 2 | Seminar | Mr. Dhanrajan, Project Lead, IDEA ZONE, Chennai | Advances in Mechanical Engineering | 25.1.22 |

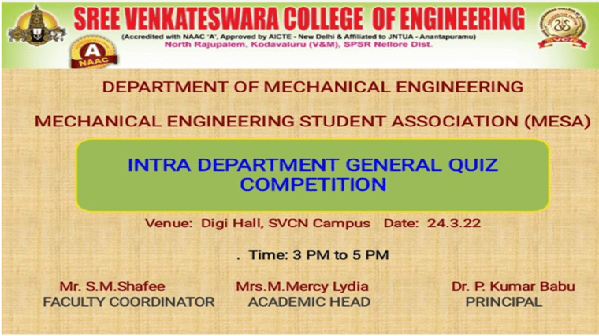

| 3 | Quiz | Mr. S.M.Shafee, Asso. Prof, Mech, SVCN | Intra Departmental General Quiz competition | 24.3.22 |

A Guest lecture was arranged on topic “Career Guidance for Mechanical Engineers”. Fareed Basha, Branch Manager, CANTER CADD, Nellore is the resource person. Students of II, III, and IV year of about 120 members attended the session.

Mr. Fareed Basha, GM, CANTER CADD delivering guest lecture on CAD & Modeling Tools

A Seminar was arranged on 25.1.2022 by MESA, SVCN on the topic “Advances in Mechanical Engineering” by Mr. Dhanarajan, Project Lead, IDEA ZONE. III, IV year Mechanical Engineering students attended the programme.

Mr. Dhanarajan, Project Lead, IDEA ZONE, delivering seminar on Advances in Mechanical Engineering

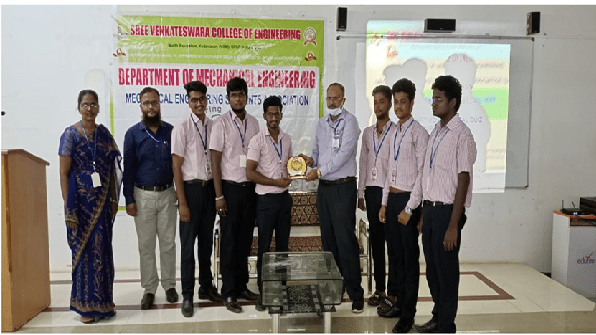

Intra Department Quiz competition was conducted on 24.3.22 as part of MESA (MECHANICAL ENGINEERING STUDENTS ASSOCIATION). Winners of the Quiz competition are III year, ME and Runners up are III year CSE. Principal Dr. Kumar Babu gave the momento for winners and runner up.

MECH Professional Society Activities

Professional Society Activities Of year 2021-22 ClickHere

Professional Society Activities Of year 2022-23 ClickHere

MEMORANDUM OF UNDERSTANDING

S.No. | Name | Department | Activities |

1 | Nelcast limited | Mechanical | Internships, project |

2 | Noobtron india pvt. Limited | College level | Research paper |

News Letter

S.No | Name of the Event | View |

1 | Halfyearly News Letter-AY-2022-23-issue-2 | |

2 | Halfyearly News Letter-AY-2022-23-issue-1 | |

3 | Halfyearly News Letter-AY-2021-22-issue-2 |

Dr.G.Vijay Kumar, M.Tech, Ph.D.

mech.hodsvcn@gmail.com

+91 9948012585